Product

The product images used are only for illustration and may not be exact representations of the product. Gulf States Saw & Machinery Co., Inc. reserves a right to amend product images or specifications at any given time.

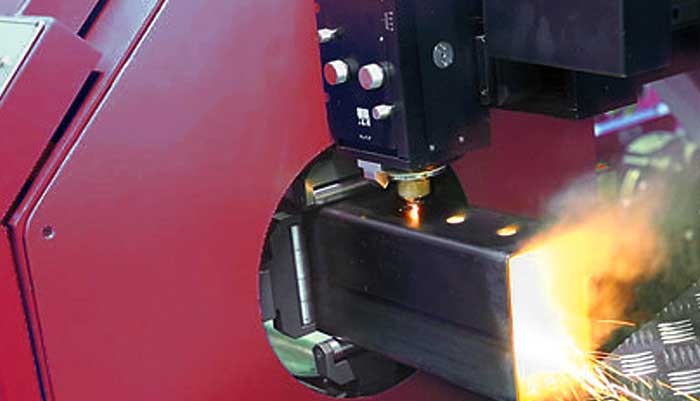

The option to choose between 2D/3D laser cutting technology allows for the possibility of customizing and precise cutting parts in a wide range of shapes. These include tubes with square, rectangular, and round shapes, as well as profiles with varied open cross-sections (e.g. H, L. T, Ucross-sections). 3D technology is capable of cutting straight edges up to 45degrees. This flexibility makes it unnecessary to perform costly milling and drilling, punching, punching, or other sawing operations.