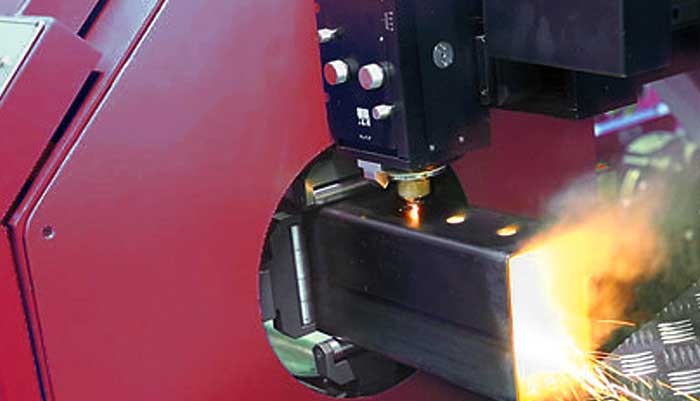

The very nature of a tube prevents the need for a machine with a very high-powered laser. Whereas flat sheet laser cutting machines now are available with laser generators as powerful as 12 kW, tube laser cutting machines usually only require a maximum of 5 kW of power. With a tube, you always have to think about the opposite side of the tube you are cutting. A more powerful laser simply would blow through the other side of the tube during cutting. (Of course, if you are processing a beam or a channel on the tube laser you donít have to worry about another side.)

How can this be compensated? Traditionally, you'd touch your face with the sensor at the contact area. The tube will then be rotated and the other end of it touched. This gives the control a good idea of the tube's bend. This technique is precise and will ensure that all through-holes work for your application. The ability to deliver very tight tolerances is affected by every rotation of a tube.