Tube Laser Cutting Systems Engineer

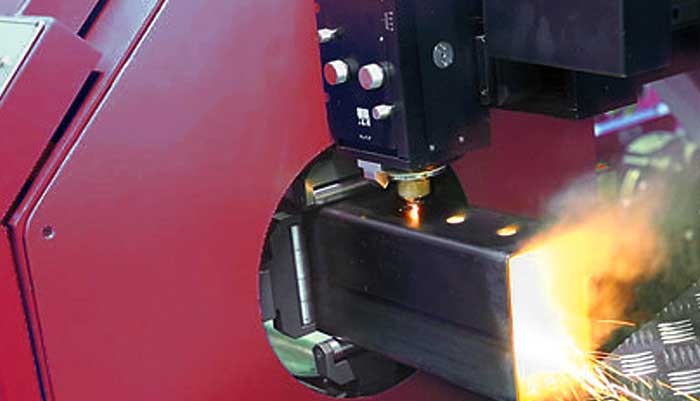

Fiber lasers are practically maintenance-free and have superior wall plug efficiency to CO2 laser cutters. They can also cut reflective materials and provide precise cutting. They can also be used to cut certain metal thicknesses faster than CO2 machines. Speed is relative when it involves cutting tube. It is possible to reduce the time required for tube processing and produce finished parts faster.

With a laser tube-cutting machine, there are no standard towers. Bundle loads are the most efficient method for handling tubes. These loaders feed one tube per bundle into the tube cutter via a singularizing mechanism. This feeding method is not compatible with open profiles such as angles or channels. Because they interlock within a bundle, and don't allow for easy release, this type of feeding doesn't work. Step loaders are employed for open profiles. These machines sequence one section at a time and maintain the correct orientation.