Milling

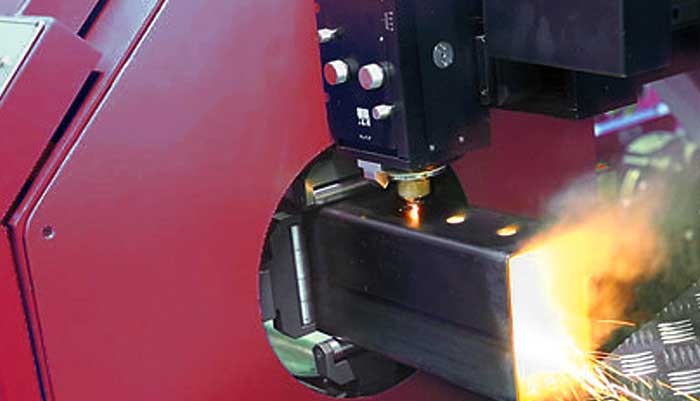

Most metal fabricators have a strong understanding of what fiber laser cutting technology has done for flat sheet processing, but just what has the fiber laser done for tube cutting? Quite a bit, actually.

It's a third of a full 20-foot (240") tube, making it convenient to create three pieces of stock. This allows you to still purchase full tube lengths without wasting any material