Can a 130w Co2 Laser Cut Metal

There are many things that you need to think about when considering purchasing a laser-cutting machine. Let's develop a detailed plan for your purchase.

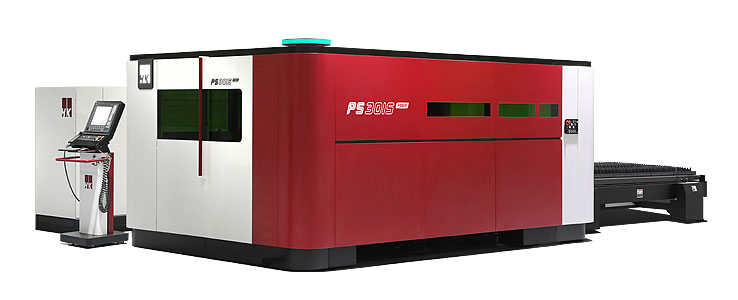

The CNC system controls technological parameters such as cutting speed and laser power, as well as movement trajectory during slitting. A specialized gas is used to blow off slag at the slit.