Sil

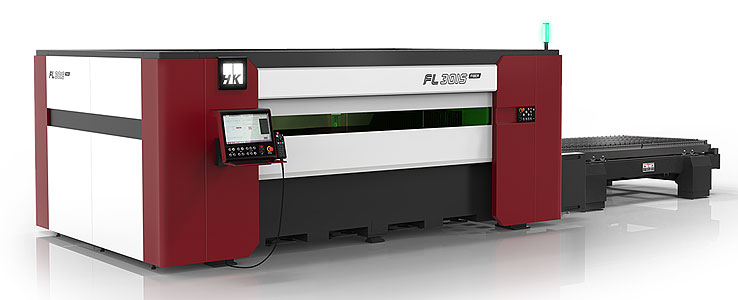

A hybrid laser cutter is an affordable combined laser cutting system with fiber laser generator and CO2 laser generator all in one machine, as well as an automated power tool that uses a high-power CO2 laser tube to mix cutting metals and nonmetals, including steel, aluminum, brass, copper, titanium, iron, silver, gold, alloy, plywood, wood, MDF, acrylic, plastic, fabric, and leather. With fiber lasers, it can cut thicker metals, with CO2 lasers, it can cut thick nonmetals and thin metals. The hybrid laser cutting table fits 4x8, 5x10, and 6x12, which can be customized as your business plans. It's the best budget laser machine for hobby and commercial use.

A laser generator is an element that produces a beam. Fiber laser generators can be used for any type of sheet metal or metal tube. CO2 lasers are cost-effective for wood, plastics acrylic, fabric leather, foam and thin metals.