What are the Disadvantages of Laser Cutting

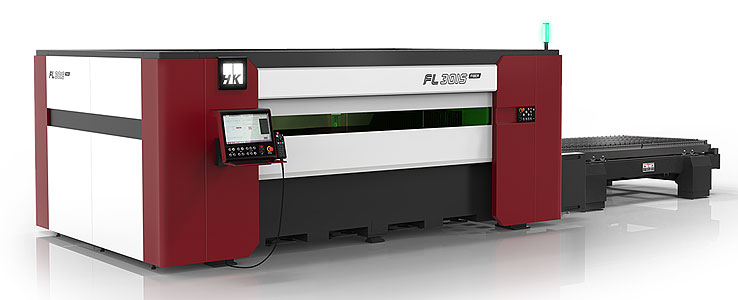

GSS Machinery high-speed CO2 Laser machines can be configured in a number of configurations to meet your application processing and budget needs.

The focus tracking system is composed an auto focus laser system and a tracking sensor. The cutting head includes mechanical adjustment parts, light guide, water cooling, and air blowing systems. The sensor is made up of the amplification control and the sensing elements. There are two types. One is an inductive tracking system (also called a contact tracking method), and one is a capacitive tracking system (also called the non-contact tracking method).