Laser Cutting Examples

If we look at the market prices of laser cutting or engraving machines, it varies on the basis of the type of work. Are you trying to use laser cutters or engravers as a hobby and looking for DIY laser machines? Good going! DIY laser machines are available for as low as 500$.

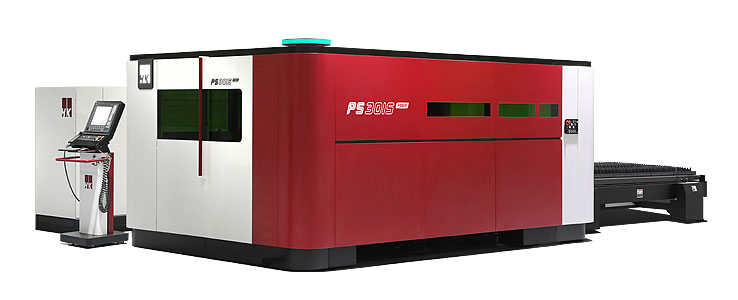

Laser cutters are used in many different applications including personalization, digital printing and medical technology.