Laser Cutting Machine Egypt

Adjust the position for the cutting head. After all preparations have been made, you are able to start cutting.

Choose the best gas for your needs, and make sure to check that the jet is still in good condition.

GSS Machinery metal- and ceramic laser tube combine the advantages of longer service life and lower costs for recharge, while allowing for better engraving and cutting.

An entry-level laser cutter can be purchased for as low as $2,600 or $8,800. It has an 80W CO2 tube laser tube. These tubes are suitable for hobbyists, amateurs, small businesses, as well as beginners and enthusiasts. High-end laser cutting machines, however, can go up to 279,000.00 with 12000W of IPG fiber laser power supply.

Our laser machines have amazing motion control, which allows them to engrave high quality graphics at super fast speeds. Images that will amaze your customers will be possible!

As the name suggests the Pergear LaserStorm S5 Laser Engraver it's on our list as it's a great engraver.

Adjust the position for the cutting head. After all preparations have been made, you are able to start cutting.

Choose the best gas for your needs, and make sure to check that the jet is still in good condition.

However, after steady developments, it is now able to cut as deep as 1.5 inches of metal. Even if they come at a higher price, they have managed to become the popular choice.

If you've got a lot of workspace, and need a general working area for your projects, then you'll love the 130W Reci W4 C02. With a generous engraving area of 1300 x 900mm, it's fast and precise, offering engraving speeds of up to 600 mm/s and cutting speeds of 300 mm/s.

GSS Machinery makes a top-quality desktop laser system. The Zing 16 includes top-quality components as well as the highest quality engraving in an affordable desktop package.

You should choose suitable lenses and nozzles, and then inspect them to verify their cleanliness.

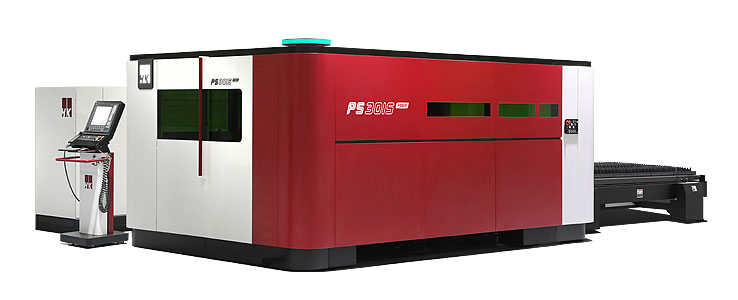

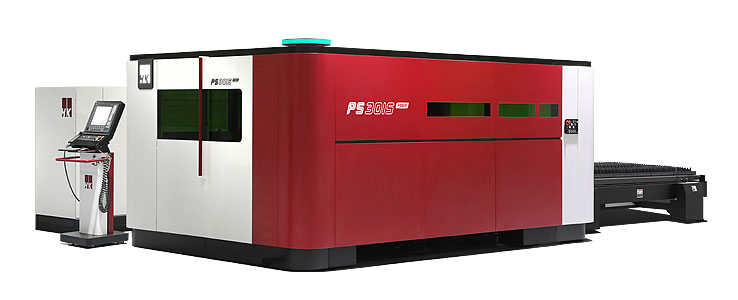

2022 best sheet metal laser cutter ST-FC3015C is the top rated full sheet metal cutting system for metal fabrication, which is suitable for custom and personalized metal signs, metal crafts, metal arts, metal logos, metal tags, metal letters, metal words. Now the best sheet metal laser cutting machine for sale at cost price.

Materials that are unsuitable for flame cutting are cut using the fusion cutting process. Materials that are typically used include alloyed steels, also known as stainless steel.

Focus the energy of the laser beam and form a high energy density spot. The medium and long focusing lens is suitable for thick plate cutting, and has low requirements on the spacing stability of the tracking system. The short focusing lens is only suitable for thin sheet cutting, which requires high spacing stability of the tracking system and greatly reduces the output power requirements.

After researching and buying the parts and accessories, the rest job is to assemble the kit and debug the software and hardware. The operation and cutting quality of the machine are directly related to the cutting material, laser generator, gas, air pressure and the parameters you set. Please set the parameters carefully according to your cutting process requirements. Improper parameter setting and operation may result in reduced cutting effect, damage to the cutting head or other machine parts, or even personal injury.

Polycarbonate is an unsuitable material for laser cutting. ABS It emits cyanide gas and melts. ABS is difficult to cut with a laser cutter. It melts rather than vaporizes, and it is more likely to catch fire and leave melted gooey deposits on the vector cutting grid.

Laser Cutting Process Drawbacks

When compared to other techniques, laser cutting requires a high power consumption.

The laser beam is extremely delicate to handle.

If the laser beam comes into contact with human workers, it is hazardous.

Laser cutting is still unable to cut thick metals.

Cutting thick materials is difficult.

The less effective laser cutting becomes as the material thickness increases. For example, when it comes to cutting thick sheets of carbon steel, laser cutting may be difficult.