What Materials Cannot Be Laser Cut

A laser cutter should be regularly maintained to ensure the cutting speed, accuracy, and quality, and extend its service life. You should form the 10 good work habits listed below.

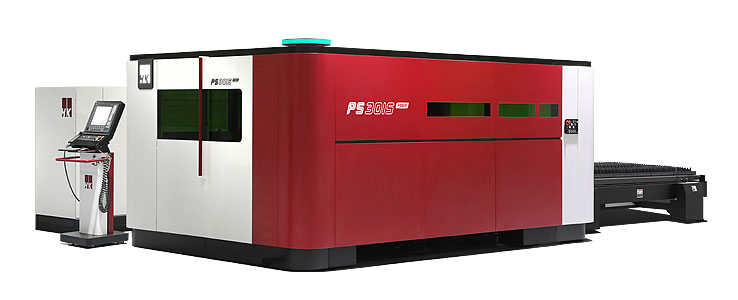

A CNC controller can be used to control movement of X and Y axes as well as set cutting parameters, such power and speed.