Advantage-2 Cnc Beam

A CNC drill line is useless if it does not position a fabricator for success in the steel fabrication industry. The Advantage-2 can process technical programs quickly and with intelligence. Each drilling axis is equipped with three five-station tool changers. They can drill, mill countersink tap, tap, and scribe. You can also equip this drill line with a Signoscript underside Scriber or Signomat Part Stamping Unit. Even after blasting, painting, and galvanizing, part information can be retained. Minimizing shop errors? Check. Check. High torque drilling axes feature a thicker, more aggressive cut that removes more chips with every rotation. This drill line can chew through beams and tube, channel, angle, tube, and flat bars. Advantage-2 has a processing window that measures 44 inches in width and 18 inches high.

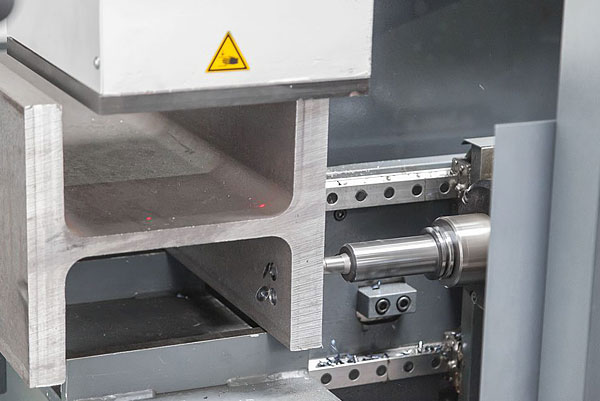

Advantage-2 carbide drills use electronic ball screw drive spindle motion and automatic tool change technology. The combination of Voortman's legendary build quality and mechanical design gives the best combination of strength, agility, and strength.