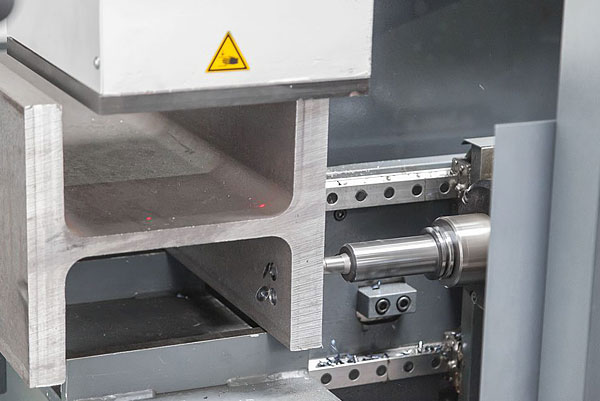

Cnc Beam Drill Line Model

The CNC Beam Drill Line operates very easily, and the majority of Avenger operator were the ones doing floor layouts. The installation requires no prior computer knowledge. All training is provided during the process.

We believe that for now, based on current pricing from the various suppliers, the customer is better off with good quality Ocean Penetrator twist drill bits and a good quality sharpener.