Cnc Beam Drill Line Quick Connect

Voortman builds machines specifically for GSS Machinery to meet our demanding specifications. GSS Machinery specifically targets the small to medium fabricator whereas Voortman targets the larger fabricators. Voortman has been building machines for GSS Machinery for more than 10 years, and GSS Machinery is Voortman largest customer worldwide.

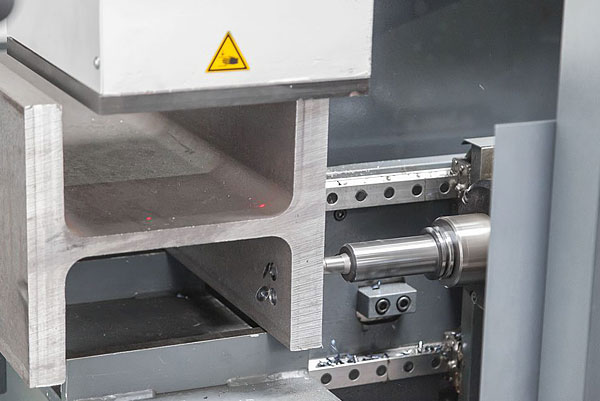

Voortman has created the CNC beam drill line standard today using proven technology. Advantage-2 processes 150 tons of steel an average of once a week. The Advantage-2 is highly efficient in drilling, milling and tapping as well as countersinking.