The UNIST MQL Coolant System has emerged as the leading coolant system in the USA over the past 10 years. It has been standard equipment for the Aveger FORTY (Plus), Avenger PLUS (Plus) and Clipper. This minimal quantity lubricant is an oil-based coolant that prolongs tool life. It is not toxic.

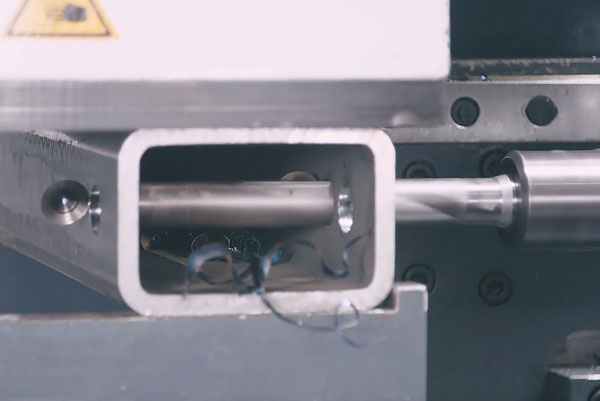

The Franklin HD145(3) spindle CNC drill is available in 44-inch width. The HD-145 can carry beams upto 750 lbs/foot. Hi-performance spindles provide drilling capabilities of up to 2,000 rpm. This rigid design delivers extremely high feed rates of up 300 surface feet per hour. You can have the Franklin HD145 equipped with various material handling packages, from 300 lbs per ft to 750lbs per ft.