Cnc Beam Drill Line Up

When deciding which CNC machinery you want to purchase, it may come between a Vertical Machining Center or a CNC router. You can use these two different pieces of equipment for many reasons for various things. Which one should...

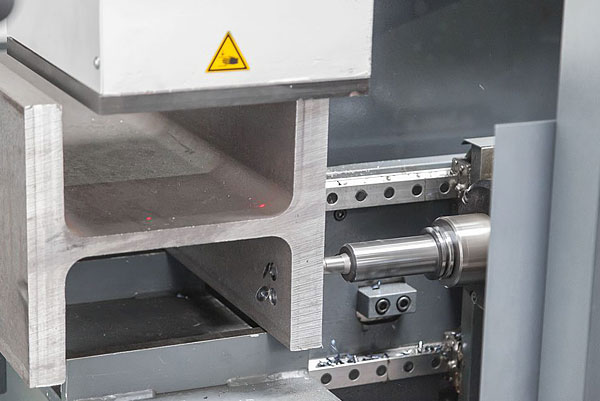

Voortman� Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.