Cnc Beam Drill Line Yield

Voortman is the only manufacturer of the CNC Beam Drill Line for GSS Machinery. Voortman takes care of all aspects of the CNC Beam Drill Line's installation, warranty, maintenance and repair. Voortman provides the service, but GSS Machinery can always be reached if required.

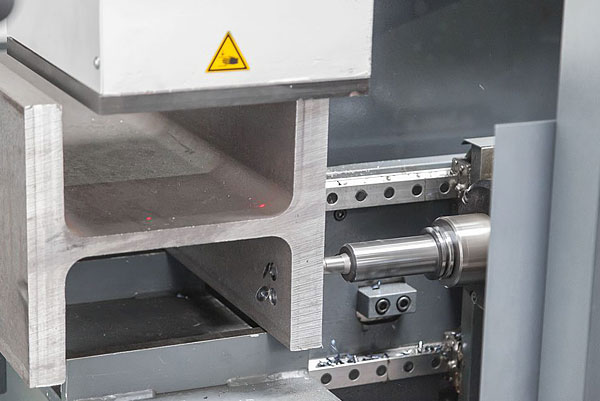

CNC Beam Drill Line is an efficient beam processing solution that requires very little floor space. It can be used for up to 70ftx9ft. CNC Beam Drill Line installations can also be found outside, which gives the fabricator more space.