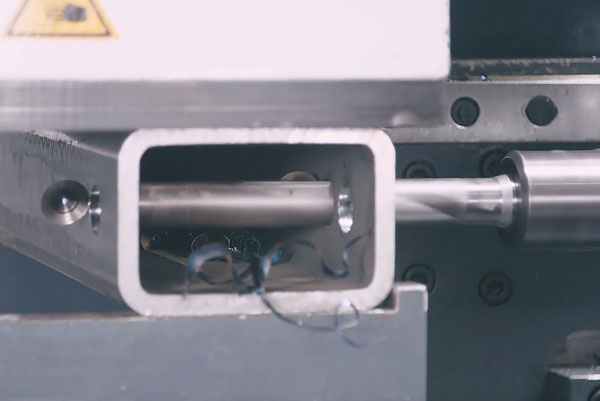

Cnc Beam Drill Line Hookup

GSS Machinery's support has been invaluable in enabling us to excel in the steel fabrication market that we currently find ourselves in.

".. This machine is designed for Structural fabricators. But I knew it would work well for drilling trucks frames. The assembly was flawless due to the machine's repeatability and accuracy. Avenger drills one channel for a truck in just two hours. We would have taken 16 hours if it was done manually. The machine has increased our productivity AND profitability !.."