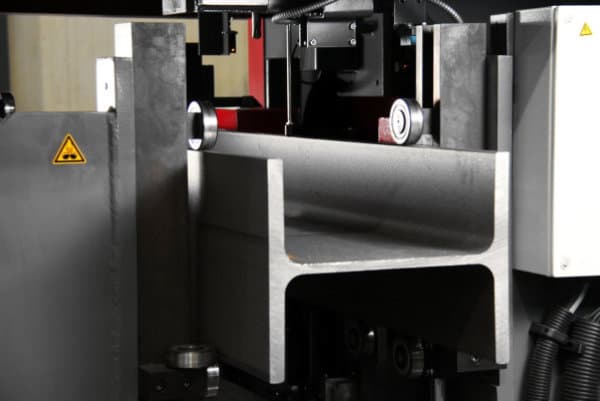

Angle Iron

Voortman's beam drilling line has intelligence beyond its own capabilities. It can also be plugged in to any environment thanks to its modularity. Tandem solutions using band saws robotic coppers and PeddiWriters increase the shop's throughput positioning. This allows the steel industry to be more economically efficient when it cools down, and more aggressive when it heats up. Voortman developed the Multmaster so that even the smallest components could be made into a tandem saw. Fabricators make greater profits by using the full profile and minimising remnant. Get more output Check. As with every Voortman CNC drill, profit would not be possible without material handling. Fabricators lose money every profile that is manually moved. Material handling is also safer than using cranes or fork trucks to transfer the largest profiles.

Z-Reader Probe-The Z-Reader Probe is a device that maps the location of the surface. It can be programmed or manually controlled. It can be disabled while cutting, and it can be pulled out of harm's reach. It can be activated to verify the surface at each pierce prior to cutting, or to drive surface mapping for the entire part before cutting begins. It is used to initialize or zero the device to the desired surface and then tracks or accumulates the difference between that zeroing effort.