Industry

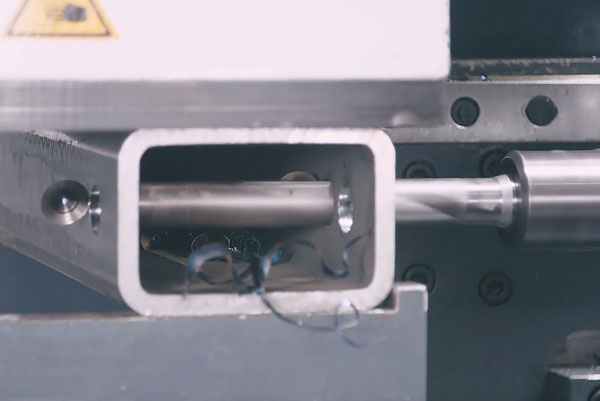

CNC Beam Drill Line is a space-saving beam processing solution. It only takes up 70ft x 9.9ft. This makes it great for fabricators with limited space. CNC Beam Drill Lines can also be placed outside, providing even more space for fabricators.

The CNC Beam Drill Line can be operated easily and Avenger operators are the ones who lay out the floor. You don't need any prior computer knowledge and are given full training at the time of installation.