Ocean Avenger Cnc Beam Drill Line Price

Voortman offers training courses at their Bradley Illinois facility on all Voortman equipment. These courses are for both new and experienced operators. The facility's graduates return to their shops highly motivated, trained, and ready to increase productivity. For pricing and details, please call.

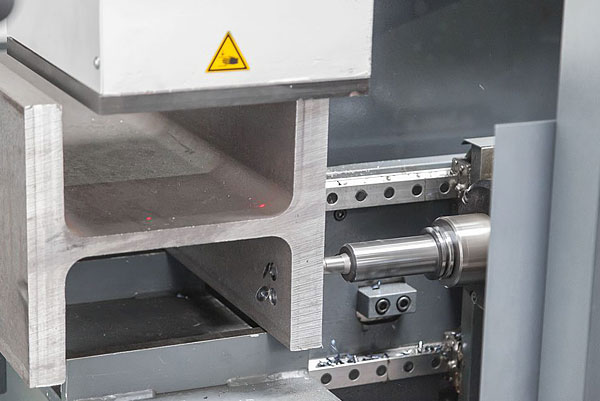

Not only will the CNC Beam Drill Line process beams and columns, but it also easily processes all steel profiles including channel, angle, flat bar, base plates, RHS, square, and round profiles.