Cnc Beam Drill Line Flow

Voortman machines are the world leaders in structural steel fabrication technology. Steel fabricators that own Voortman machines uphold an advantage in the steel industry and have the ability to optimize tonnage capacity. The Advantage-2 CNC beam drill line is the backbone of any structural steel fabrication shop. High-speed, multi-spindle, relentless carbide drilling is the very core of this machine. The design of the Advantage-2 has created one of the most profitable drill lines in the steel industry. A heavy steel frame ensures this drill line will support shops for the long haul. The Advantage-2 can run profiles end to end with no stop in production all thanks to the roller feed design on the infeed and outfeed. Hundreds of fabricators across the globe run hundreds of thousands of tons of steel through their Advantage-2s year after year.

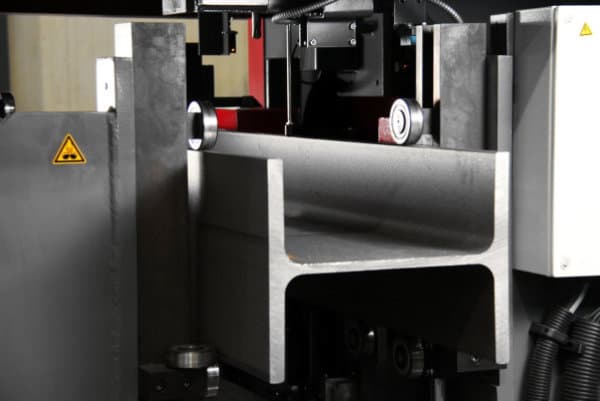

Voortman's Roller Feed Measurement System exceeds industry standards for roller measurement technology. It is essential to ensure that accurate measurements are taken without any delay in production. Even if there are slight variations in the material, accuracy is maintained.