9 Craftsman Drill Press

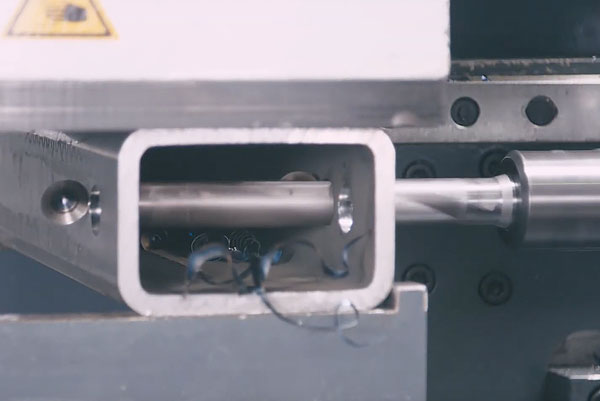

The CNC Beam Drill Line, which can be used to fabricate structural steel or miscellaneous metallics, was immediately a hit with small to medium size fabricators. Since 2003, more than 600 CNC Drill Lines were installed all over the globe. This incredible machine has transformed the lives many a steel fabricator.

CNC Drill Line is specifically designed for fabricators or general job shops who need to drill holes through steel profiles of all kinds. The following questions can help you decide if this machine is right for your needs.