Lincoln Drill Chart

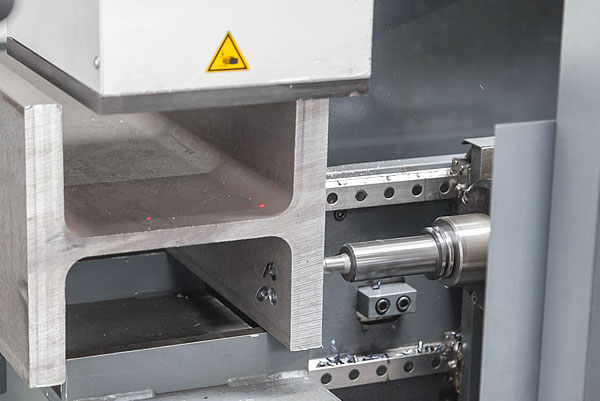

Z-Reader Probe- This probe maps the surface's location. It can be operated manually and programmatically. The option is removed from danger and is not active while the cutting process is underway. It can be used for surface mapping or to verify surface at each point before the cutting process begins. It is responsible for initialization, or zeroing the device on the surface at beginning of a program. From there it tracks the difference or accumulates them.

Even if you are programming the CNC Drill Line manually, it is easy to program. Peddimat machine programming software can be used and most operators will learn how to program most of the parts in under an hour. Of course practice makes perfect. It is best to program the machine by importing parts directly from a 3-D modeling program such as ProSteel 3D, StruMis, Tekla Structures, SDS/2 or StruMis. These files are imported directly into your machine. Once you have selected the part, hit the Cycle Start button.