Q Drill Size

Based on the pricing at the various suppliers, we believe that the customer will be better off purchasing good quality Ocean Penetrator drill bits and a high quality sharpener.

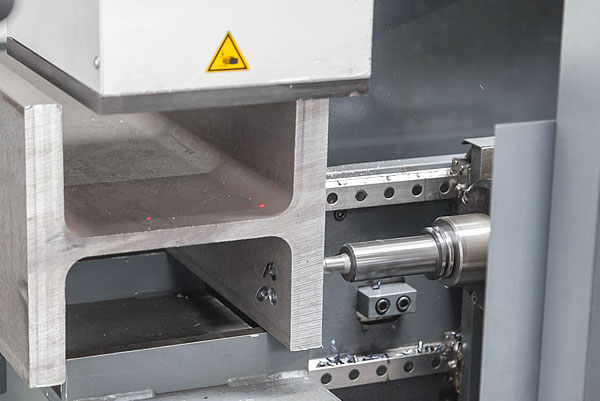

The CNC Drill Line can lay out and drill all of your holes in any type of steel profile in fractions of the time that it takes to do manually with a mag drill. It also marks all your welded attachments, eliminating the need to use a tape measure.