Auto Stand-Off � This is currently defined to be surface stand-off and not to be confused with vector stand-off in 5-axis mode. The current auto stand-off is based on a changing surface and will adjust vertically based on the angle of the �A� Axis, so there is five (5) axis taken into account during the calculations, but this is not the same as the tool vector stand-off. There is the ability to do the vector stand-off change while the machine is running manually with buttons on the screen.

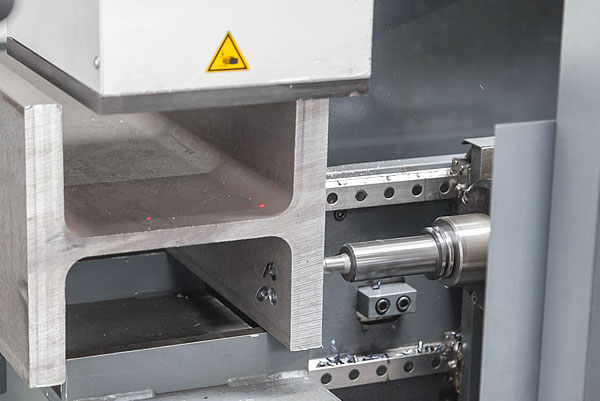

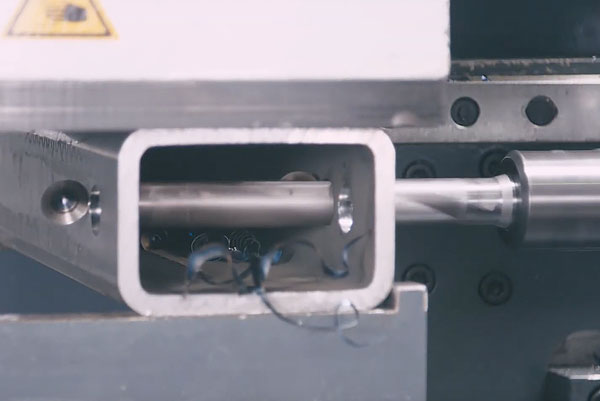

Our beam drill machines have central lubrication, a cooling system, and linear guides to make them easier to use and require less maintenance. Each coordinate system includes a 4 station tool changer. This allows it drill, mill/scribe, counter sink or tap as many times as required. Additionally, tools can be swapped easily during operation. Positive beam positioning is an arm that attaches to a rack on the conveyor. This allows the beam position to be more precisely controlled as it moves through a drill line.