Flat Bar

It is better to import files directly form your steel detailing program. This removes an unnecessary step as well as eliminates potential incorrect data capture. Two distinct camps exist in this regard:

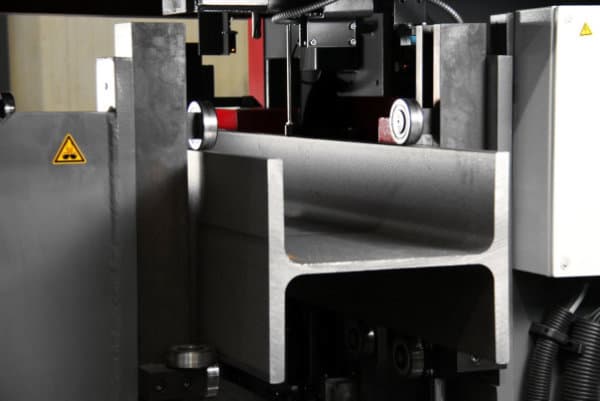

Advantage-2 uses a variety of support clamps to ensure maximum rigidity through the machine. Carbide tool life can be extended by reducing vibrations as much as possible.