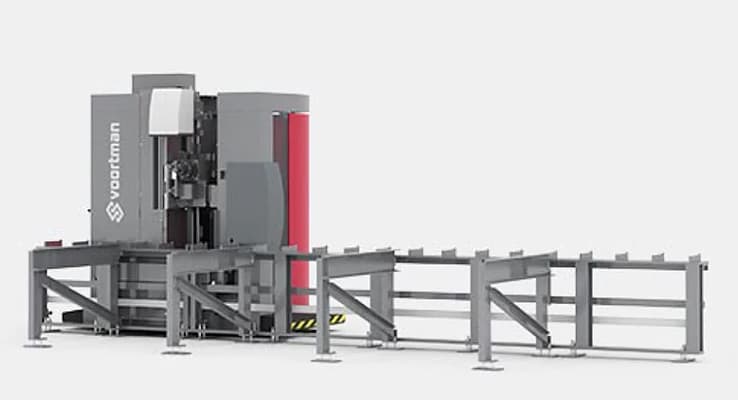

It doesn't matter if a CNC drill isn't able to position a steel fabricator to be competitive in the steel fabrication market. The Advantage-2's ability to process technical files with intelligence, speed and precision is what makes it so special. Each drilling axis can operate with three five-station tools changers. Signoscript's underside scriber and Signomat's part stamping unit can be attached to this drill axis. Part information is preserved even after galvanizing, blasting, and painting. Minimizing shop errors? Check. Advantage-2 uses carbide tooling to drill more holes and is more aggressive than any other drill. High torque drilling instruments have a thicker and more aggressive cut which removes more chips from each rotation. This drill can remove beams, channel and angle tubes as well as flat bars. Advantage-2's processing window is 44 inches wide by 18 inches high.

The programming of the CNC Drill Line can be done intuitively even by operators who have never used a computer or CNC.