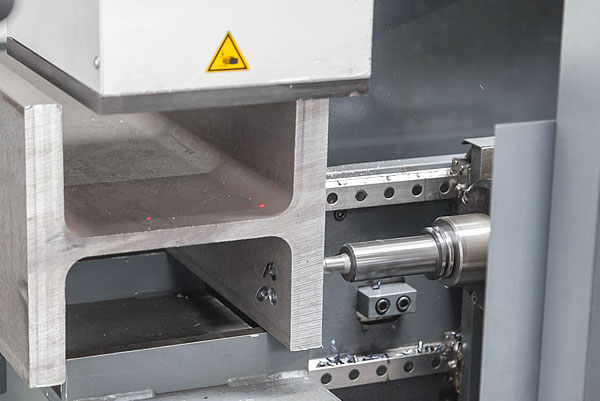

Cnc Drill Line Attachment

The attachment for 4-axis layout marking eliminates human error in manual layout. Even after galvanizing, blasting, and painting, part information can be retained.

Importing files directly from steel detailing software is preferable. This eliminates the need for additional steps and eliminates any potential errors in data capture. In this regard, there are two distinct groups: