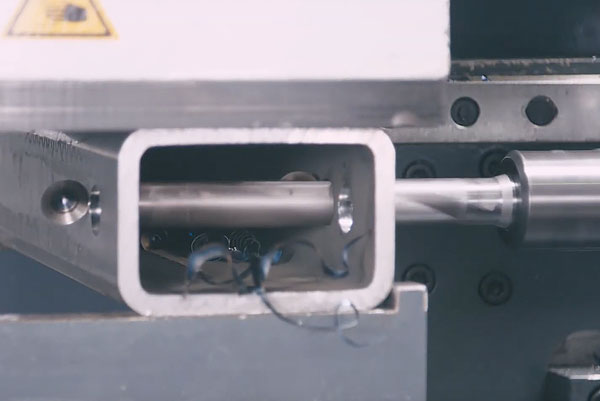

Let's see how Twist Drill Bits are compared to Insert Drill Bits in real life. One example will be shown - 13/16 inch (22mm), the most frequently drilled hole size.

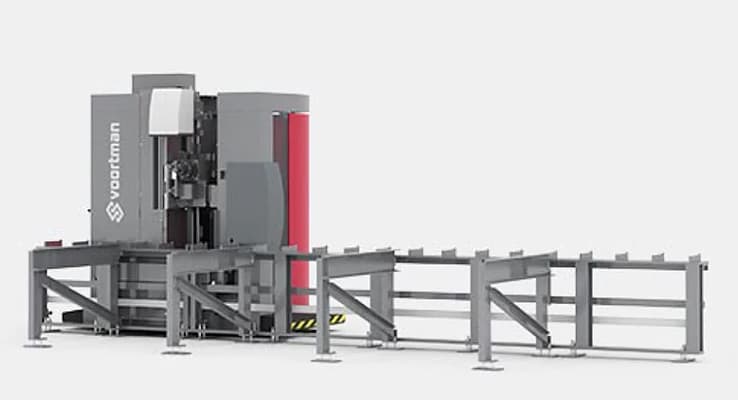

If a CNC drill machine doesn't allow a fabricator the ability to compete at the highest level in steel fabrication, what good is it? The Advantage-2 is able to process technical programming with intelligence and speed. Each drill axis comes equipped with three five station tool changers. These can be used to drill, mill and countersink as well as tap and scribe. Signoscript underside or Signomat part stamping units can be added to this drill line. You can keep your part information even after you have finished painting, blasting, or galvanizing. Minimizing shop errors? Check. The Advantage-2's carbide tooling allows for more aggressive drilling and more holes per hour than any other drill line. The high torque drilling tools have a more aggressive cut, removing more chips each rotation. This drill line is capable of cutting through beams, channels, angles, tubes, and even flat bars. Advantage-2 can handle any profile with a processing window of 44inches wide by 18inches high.