For 50 years we have been developing machines and solutions for you as a steel fabricator. We focus on automation as a response to the ever-decreasing ability to find quality labor and rising labor costs, so you can lower your overall production costs and increase your margins.You can ensure the utmost productivity, accuracy and reliability with one of Voortman�s CNC Beam Drill lines. Our CNC Beam Drill Lines integrate many functions like drilling, milling, marking, countersinking, thread-tapping and more to increase capacity and automation and optimize your workflow. Due to Voortman's complete range of advanced Beam Drill Lines, there is a suitable Beam Drill Line solution for every type of production or company.

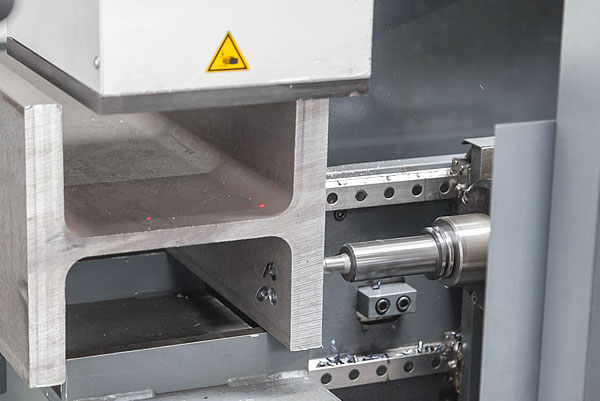

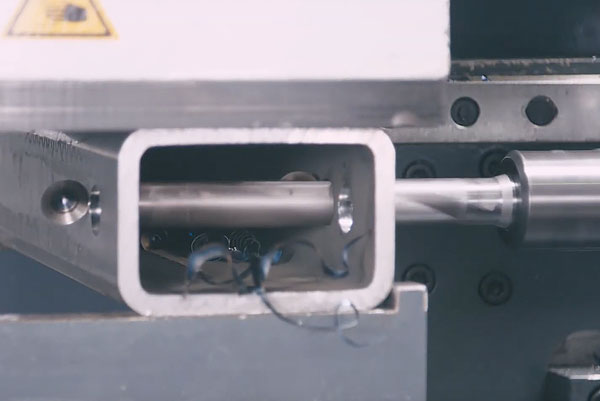

Our beam drill line machines feature central lubrication and linear guides. This ensures smooth operation and less maintenance. Each coordinate system has a 4-station tool changer that allows it to drill, mill and scribe as well as counter sink or tap. It can also swap tools mid-operation without any disruption. The positive beam positioning system consists of an arm attached on the feed conveyor to a rack-and-pinion system. This allows the beam to be positioned more precisely as it passes through the drill line.