Avenger Cnc

Material handling allows fabricators to connect multiple CNC machines and keeps material moving through their shop, allowing them to grow with the business. The Advantage-2 high speed drill line can process up to 150 tonnes of steel per 40-hour work week. This drill line is ideal for small and large fabricators all over the globe. Stop. Voortman is committed to the success of the steel industry. Our support and service are unmatched. To learn more about the most powerful steel fabrication machinery, request a demo, quote or visit. Voortman is stronger than steel.

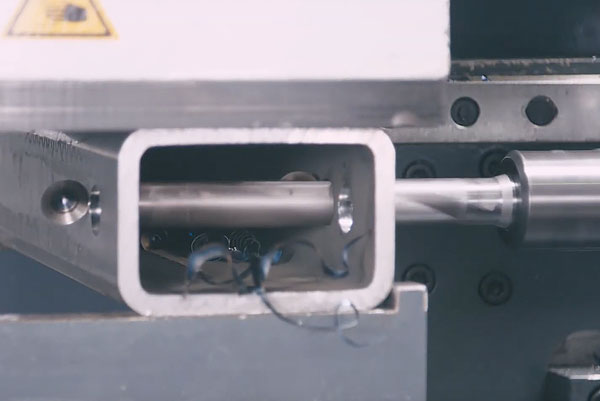

The UNIST MQL lubricant has evolved to be the most popular coolant system in America over the past ten years. It is now standard equipment on Aveger FORTY, Avenger PLUS, and Clipper. This low-intensity lubricant, which is oil-based, promotes longer tool life. It is safe for use.