What materials Cannot be laser cut

Boss Laser will pre-assemble your FM-Desktop. They also offer technical support on-site to customers.

FSL Muse Pandora's 20W version can deep engrave sterling at a speed up to 708 ipm using 100% of its laser power.

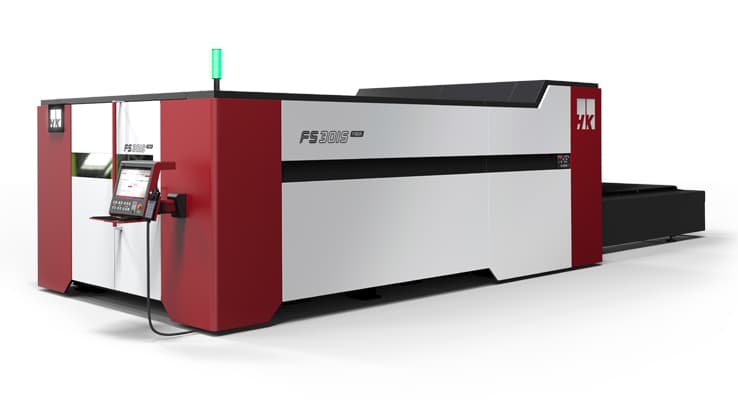

Fiber lasers are revolutionizing the laser metal cutting industry with their low maintenance cost and higher cutting efficiency.

In laser engravers, a mirror galvanometer is a series of mirrors in the laser head that move extremely fast to manipulate the path of the laser. A small rotation of 10 degrees at the head is enough to produce 1 3/4" inch of movement at 10 inches. It is also used to trace out the laser paths before engraving or cutting.

1000W/2000W/3000W fiber laser cutter is used for cutting metal parts, arts, crafts, signs, signage, logos, letters, texts, kitchenware, and more sheet metal fabrication plans. Now the best fiber laser metal cutter for sale at cost price.

It is important to remember that a fiber laser has limitations in terms of both the size of your work-bed and the material you can cut.

Boss Laser will pre-assemble your FM-Desktop. They also offer technical support on-site to customers.

FSL Muse Pandora's 20W version can deep engrave sterling at a speed up to 708 ipm using 100% of its laser power.

They also provide a 30-day return policy and 2-year parts warranty for all the components and the fiber laser in FM-Desktop.

This basically means that when working on materials such as metals which reflect laser beams, fiber laser radiation will absorb at a higher rate than laser generated by CO2 lasers.

If you�re cutting metals that are highly reflective, like aluminum, copper, or brass, and they are in the thicker side of cutting, then a plasma will be ideal. Lasers machines usually struggle with cutting reflective metals, especially if they are on thicker side. You�ll see that if you want to cut reflective metal, then you�ll need a higher amount of power to do so. And more power means more $$$.

High-concentrated power lenses with a longer focal length are used to expand the engraving area.

The laser module lasts for 100,000+ hours and can be used with a repetitive precision of +0.00039".

Fiber laser machines are better at cutting thin metals than other types of cutting machines. A fiber laser machine is capable of cutting thin metals up to 25mm (or 1 inch). Fiber lasers then start to cut metal less efficiently. To cut ticker metals larger than 25mm or 1 in., you would require a high power laser, which will cost you a lot more.

The beam quality for 20W, 30W, and 50W lasers is less that 1.5 M2, while it is less then 1.8 M2.

A 30W fiber Laser can engrave on stainless Steel at a 90deg angle, with a speedy speed 3,543 ipm.

Fiber lasers leave unsightly marks on wood.

The goal of any marking or engraving project is to create a readable mark, whether by hand or machine. Uncontrolled absorption, on the other hand, results in an uncontrolled mark on the wood.

Applications for the 50 Watt Fiber Laser Deep Engraving Machine:

Thin metals such as stainless steel, aluminum, alloy, brass, silver, gold, and titanium can also be cut by the deep laser engraving machine.

Marking and engraving are improved by high peak power and nanosecond pulses. The increased power and improved beam quality result in cleaner cut edges and faster cutting speeds. Fiber lasers are also used in material processing, telecommunications, spectroscopy, medicine, and directed energy weapons.