Light

Contact them via phone, e mail, or social media for after-sales assistance

Fiber lasers can be used to engrave metals more efficiently than the generic CO2 lasers.

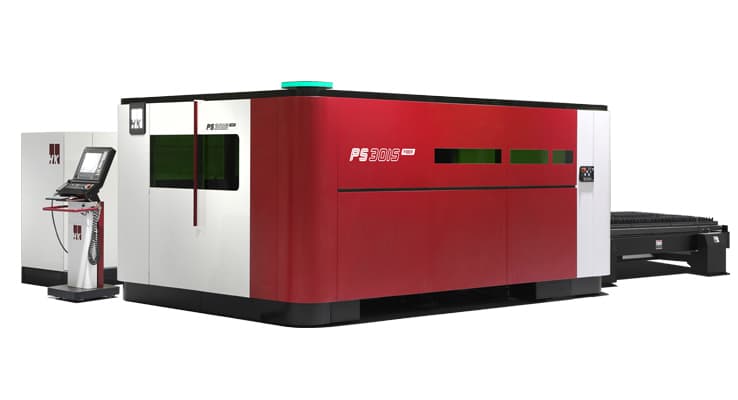

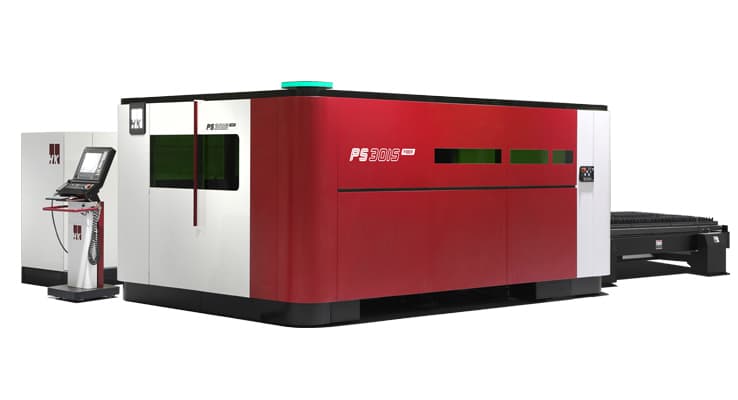

6x12 high power fiber laser metal cutting machine with exchange pallet has faster cutting speed and high power laser source (1000W, 2000W, 3000W, 4000W, 6000W, 8000W, and up to 40000W) compared to other cutting solutions for commercial use, now the high power laser cutting machine for sale at affordable price.

Fiber lasers can be used in laser engraving and laser marking machines. A fiber laser is able to laser cut sheet metal, which is the main difference between it and a CO2 laser.

Fiber lasers utilize laser light to stimulate the active medium.

With the CNC control system, the fiber laser cutter is equipped with a laser generator to dope the pump material into the optical fiber, and the laser of a specific wavelength emitted by the semiconductor laser is coupled to make the optical fiber generate laser light. Then, the machine converges the laser beam into a small diameter spot to form a beam of high energy density and extremely bright light, which acts on the metal to be cut, which causes the temperature of the metal at the laser irradiation point to be sharp it rises and reaches the vaporization temperature instantaneously, causing evaporation and forming holes. And the machine uses this as the starting point, according to the shape requirements of the part to be cut, the laser beam and the part are moved relative to each other according to a certain trajectory to form a slit. At the same time, the auxiliary gas blowing device is used to remove the slag.

Contact them via phone, e mail, or social media for after-sales assistance

Fiber lasers can be used to engrave metals more efficiently than the generic CO2 lasers.

Customers can access a community website. You can also find small communities on Facebook.

CNC metal pipe laser cutting machine with automatic feeding system for loading & unloading can meet round tube, square tube, rectangular tube, flat tube, flange beam, channel beam, U-tube, and all types of shaped tubes and pipes cutting.

MCWlaser PRO can be used on steel, stainless steel and silver as well as alloys, aluminum, and other metals.

AMADA introduces the world�s first fiber laser cutting system with Locus Beam Control (LBC). LBC Technology can freely manipulate the laser beam to create an infinite number of locus patterns and greatly enhance cutting performance.In conventional fiber laser cutting systems, energy density reduces as material thickness increases, resulting in alack of effi ciency. In marked contrast, LBC Technology offers flexible beam pattern control matched to each application,while retaining high-efficiency cutting and high energy density. As a result, VENTIS achieves cutting speeds up to 3times faster than a conventional 4kW fiber laser while producing superior edge quality.

You can access the software interface simply by entering your machine's IP address in browser's address field.

Boss Laser provides technical support through engineers and technicians for customers for life.

One thing to note is that while using a fiber laser, you will be somewhat limited in the work-bed size and the range of materials you can cut.

Based on the 3D data, the auto-focus feature automatically adjusts laser head position along Z-axis.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Fiber lasers typically cost between $20,000 and $45,000.

What Materials Can Be Cut With A Fiber Laser? A fiber laser cutting machine can cut sheet metal such as carbon steel, stainless steel, copper, brass, aluminum, and titanium. Fiber lasers outperform CO2 lasers in cutting reflective materials.