Fiber Laser Machine Uae

Boss Laser offers CorelDRAW 2020 as an add-on to the FM-Desktop machine.

However, fiber lasers cost a lot so you'll need to look into diode-type lasers if you want a cheap laser engraving machine.

FSL Muse Pandora includes a mirror-galvanometer in its laserhead that tracks the laser path and gives an estimate of the cuts it will make.

At the same time, the high-precision 3D robot fiber laser cutter has important strategic significance for improving the level of aerospace technology equipment. As the laser volume becomes smaller, the power increases and the auxiliary devices continue to improve for thick plate cutting and large format metal fabrication. The laser generator, power supply, host, control system and cooling circulation device are closely combined to form a complete set of compact laser cutter with small footprint and perfect function.

Advanced designing can be done with other CAD programs, such as Photoshop, AutoCAD, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDRAW, CorelDraw files in JPG, DXF and PNG, DXF and BMP file formats, DXF and PCX

Laser power options include 1000W, 1500W or 2000W. We also offer 2500W, 2500W, 3000W, and 3000W. These fiber laser machines can cut at a speed of 35 m/min and are capable of high-level precision. Laguna Tools offers machines with enclosed work areas to reduce light pollution.

Boss Laser offers CorelDRAW 2020 as an add-on to the FM-Desktop machine.

However, fiber lasers cost a lot so you'll need to look into diode-type lasers if you want a cheap laser engraving machine.

Mirror galvanometers can be found in laser engravers. These mirrors move very fast to direct the laser's course. A simple rotation of 10 degrees at your head is sufficient to produce 1 1/2 inches of movement at ten inches. It is also used before engraving and cutting laser paths.

FM-Desktop mobile engraver machine has a footprint measuring 33.5" x 24,.5" It can mark on 4.33"x4.33" which is great for small projects like laser engraving knives.

Fiber laser machines are more efficient in cutting thin metals. A fiber laser can efficiently cut thin metals to 25mm, or 1 inch. After this point, fiber lasers become less efficient at cutting metal. You'd need to use a lot of power, which would also cost more, in order to cut ticker metallics over 25mm or one inch.

A 30W fiber laser can be used to engrave stainless steel dog tags at a 90 degree angle. It uses 70% of the laser's power.

The laser beam generated by the amplifier is then fed to cutting heads using a flexible optic fiber.

Triumph's 30-W desktop fiber laser can be used to create two lenses. The first gives you a 4.3 inch x 4.3 inch engraving area and the second gives you a 7.8 inches x 7.8".

A fiber laser can be limited in both the size of the work-bed and the materials that you can cut.

The laser energy delivered at the laser spot will increase the closer the M2 value to 1. It can process thicker materials through narrow deep wells.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

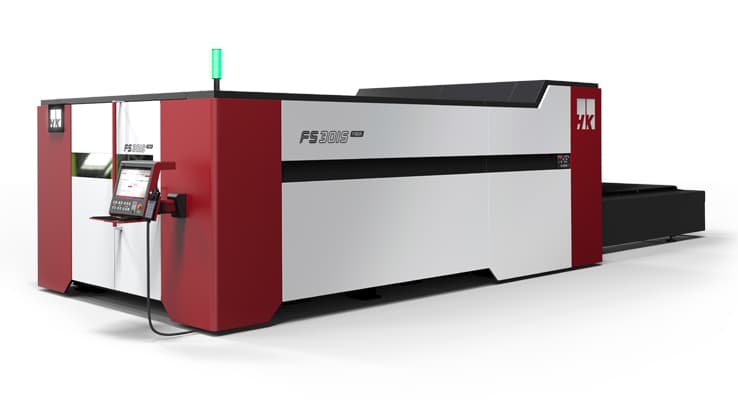

Laser fiber cutting machine

Fiber optic laser cutters are intended to cut metal at high speeds and with pinpoint accuracy. These machines, which have been on the market for more than 20 years, also use a fiber laser power source.

Thin carbon fiber mat can be cut with some fraying - but not when coated. The laser can cut or etch. The laser can cut materials such as wood, paper, cork, and some plastics.