Can you laser etch titanium

The laser arm is held by the support column (Z-axis). You can adjust the laser focus by moving the Z axis with the height adjustment knob.

Fiber lasers absorb much more energy than CO2 Lasers.

It is a pulsed fibre laser with a wavelength 1064 nm. It is expected to last for approximately 25,000 hours.

Although fiber lasers may be solid-state lasers they are not as powerful as diode or other lasers.

FSL Muse Pandora uses a mirror galvanometer to trace the laser path and give an idea of what cuts it will make.

Fiber lasers are solid state lasers that are widely used in laser marking and engraving machines. Laser cutting sheet metal is the major difference between a fibre laser and a co2 laser.

The laser arm is held by the support column (Z-axis). You can adjust the laser focus by moving the Z axis with the height adjustment knob.

Fiber lasers absorb much more energy than CO2 Lasers.

You can import file types like PDF, SVG, JPG, BMP, and more into RetinaEngrave v3.0 from any CAD software of your choice.

A fiber laser is the best choice if you want to laser cut/engrave aluminum, brass and other metal workpieces.

Gulf States Saw & Machine Co. uses a Raycus 50W fiber laser solid-state with a lifetime 100,000 hours.

But we all know cost does not just stop when you first buy a laser machine. Both laser and plasma have cost associated with them for operating and maintenance. Things you need to consider are stuff like power consumption, maintenance, consumables, and labor (how much time/money it cost to operate the machine).

After considering their dimensions, material capabilities, laser powers, upgrades, maintenance, service and assembly, the laser safety, linear motion and software use, I decided to purchase these fiber laser-engravers.

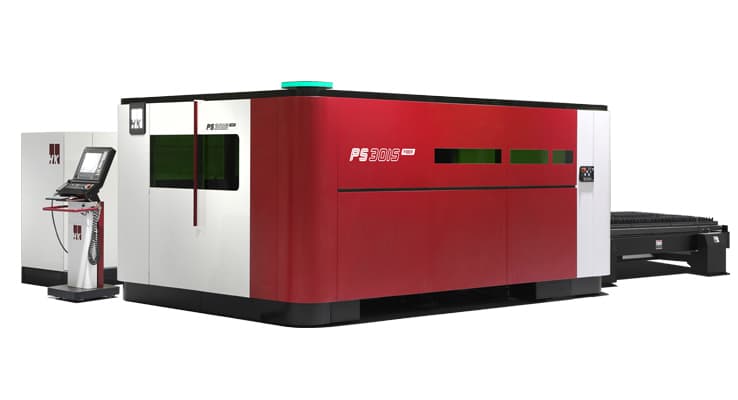

AMADA's 3kW, 6kW, 9kW, and 12kW ENSIS fiber laser technology utilizes a highly innovative resonator to automatically and precisely adjust the diameter of the laser beam. This unique feature enables continuous processing of thin-to-thick materials by a single machine with no lens change or additional setup required.

Gulf States Saw & Machine Co. (FM1212-50S) does not include assembly. The modules can be attached to the machine by simply referring to their manual.

Gulf States Saw & Machine Co., newest laser machine combines our top-of-the-line technology and our latest features in a compact desktop format, with a 30-watt fiber option for marking metals and engineered plastics.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Fiber lasers typically cost between $20,000 and $45,000.

What Materials Can Be Cut With A Fiber Laser? A fiber laser cutting machine can cut sheet metal such as carbon steel, stainless steel, copper, brass, aluminum, and titanium. Fiber lasers outperform CO2 lasers in cutting reflective materials.