For advanced designing, you can use other CAD programs (like Photoshop, AutoCAD, CorelDRAW) and import files into EZCAD2.0 in JPG, DXF, PNG, PLT, PCX, DXF, and BMP file formats.

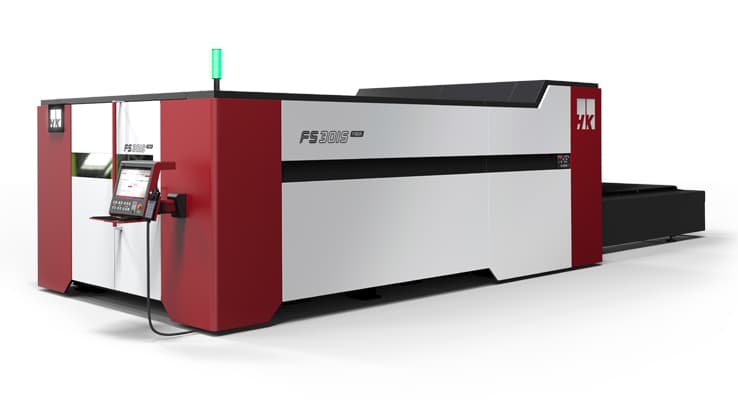

Laser cutting machines are expensive at first. They can cost 2x more than a plasma cutter initially. A plasma machine cost starts somewhere around 40,000+ and a laser machine is about 80,000+. Off course this depends on where you buy your metal cutting machine and how powerful it would be. There are some plasma machines that are as low as 15,000 and laser machine as low as 50,000. But like I said, it all depends.