Fiber Lasers Machinery Quizlet

It will provide the required speed and power rate for aluminum and steel, blackacrylic, lexan and granite.

The generated laser beam is then amplified and fed to the cutting head using a flexible optical fiber.

Fiber lasers can be used to engrave many applications. The wavelength range of fiber lasers is 780nm � 2200nm.

How plasma works can get a little complicated. So, I�m explain as simply and quickly as possible. Plasma cutters basically heat up gas so much that it gets hot enough to melt metal. Then, when the metal is heated up enough to melt, it is blown away with gas to make the cut. There�s a complicated science behind this, but I�ll save that for another day! (or you can research on your own if you like).

At the heart of a fiber laser is the laser source and they do not have any gaseous medium in it like in a CO2 laser.

Plasma, on the other side, can efficiently cut any metal up to 80mm thick and 3 inches in diameter. When cutting thicker materials, plasma can begin cutting much faster than laser.

It will provide the required speed and power rate for aluminum and steel, blackacrylic, lexan and granite.

The generated laser beam is then amplified and fed to the cutting head using a flexible optical fiber.

Fiber lasers are the best option for laser cutting/engraving aluminum and brass workpieces.

Finally, the laser beam will be projected onto the work material and is focused at the cutting head.

Fiber lasers are limited in their focal point. This makes it difficult to use them to cut thicker materials. A CO2 laser is the best choice in such situations.

Triumph's 30-W desktop fiber laser is able to engrave metal parts and tools, including aluminum, gold, stainless steel and copper.

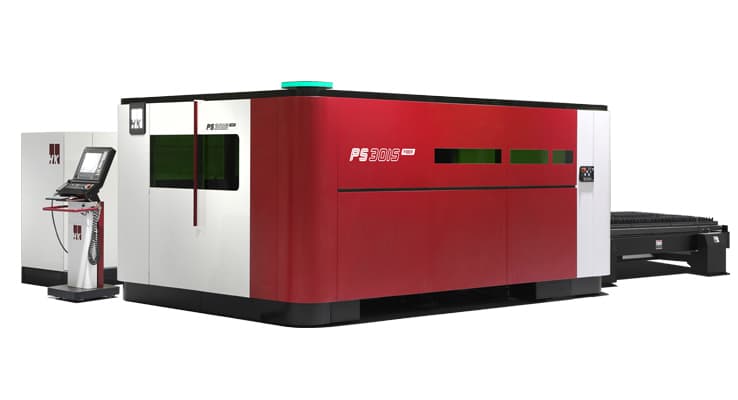

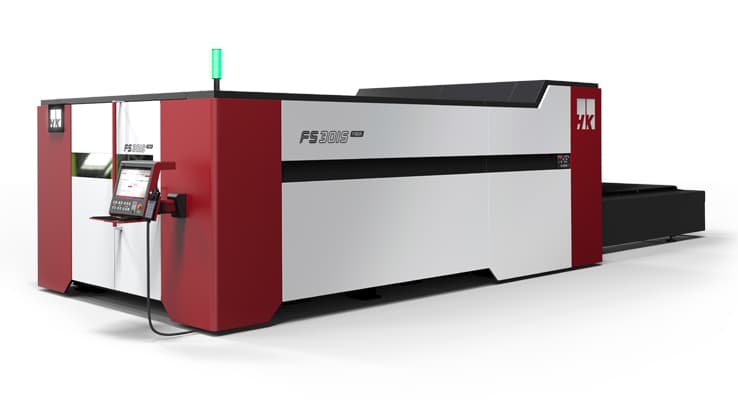

Fiber lasers are changing the industry in laser metal cutting with their low maintenance and high cutting efficiency.

They offer a 30-day return policy as well as a 2-year parts warranty on all components and the fiber laser in FM�Desktop.

Combined with intuitive, easy-to-use, high-speed CNC control units that help operators make short work of any task, fiber lasers are perfect for helping you achieve cost-effective, high-accuracy machining in nearly any situation.

Plasma can, however, cut any type or metal up 80mm thick or 3 inches thick. Plasma can start cutting quicker than laser when cutting thicker material.

Compressed air, nitrogen, oxygen, and argon are the four primary types of assist gas for fiber laser machines.

Maximum material cutting thicknesses by 1000W fiber laser cutting machine: Carbon steel has a maximum thickness of 10mm; stainless steel has a maximum thickness of 5mm; aluminum plate has a maximum thickness of 3mm; and copper plate has a maximum thickness of 3mm.

To guide light, fiber lasers use an optical fiber cable made of silica glass. Because the resulting laser beam is straighter and smaller than with other types of lasers, it is more precise. They also have a small footprint, are energy efficient, require little maintenance, and have low operating costs.