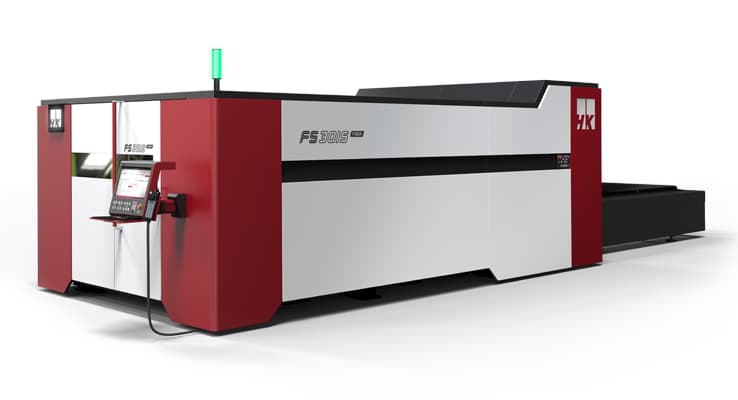

Fiber Cutter Machine

Oxygen is often used in the laser cutting process, and sparks flying during the cutting process can easily cause fire. Therefore, there should be no inflammable and explosive materials in the working area, and corresponding protective facilities should be provided at the same time.

FSL Muse Pandora is upgradeable with a special focus lens, a rotary-axis, extended Z-travel, fume extractors, and fume extractors.