Fiber laser is a type of high energy laser beam based on fiber amplifier that uses glass fiber doped with rare earth ions as the gain medium. The pump light irradiates the rare-earth-doped glass fiber pump source, which induces the rare-earth ions to absorb photons, and the excited radiation has the same frequency as the incident photons. Under the action of pump light, it is easy to form high power density in the fiber, which results population inversion of the laser working substance. When a positive feedback loop (constituting a resonant cavity) is properly added, the laser oscillation output can be formed. Fiber lasers have a wide range of applications, including material processing, communications, medical beauty, scientific research and military, instrumentation and sensors. It has been used for cutting, engraving, etching, marking, welding, surface treatment, cleaning, cladding, and some other applications.

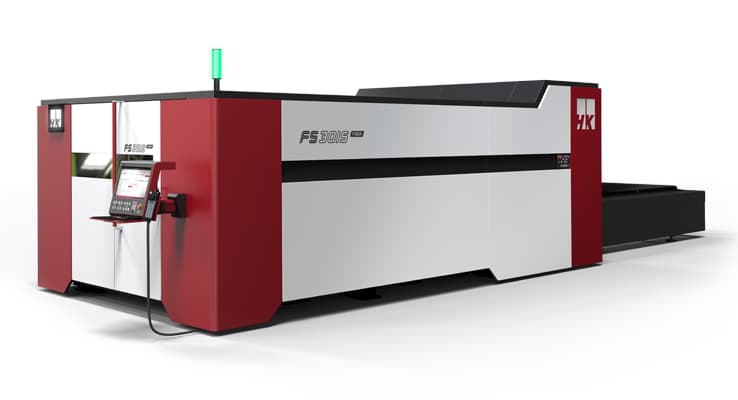

Gulf States Saw & Machine Co., Fiber Laser series is your solution for etching and marking all types of bare metals and plastics. Whether you're looking to mark metal with barcodes, logos, and serial numbers, or you're personalizing metal items such as watches, jewelry, and medals, an Epilog Fiber Laser system has the features to help you accomplish your goals.