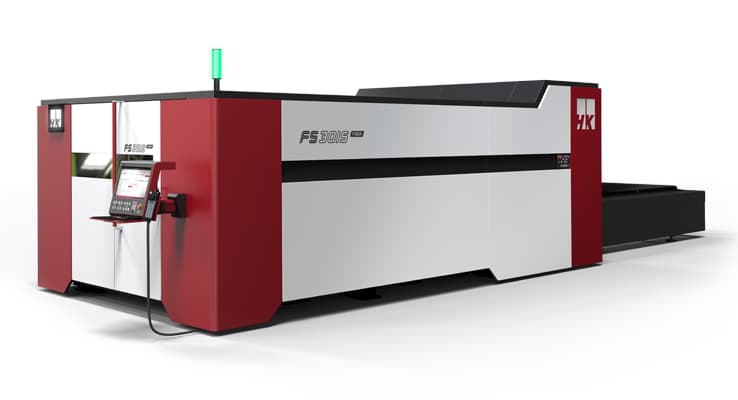

The REGIUS 3015 AJ fiber laser is the pinnacle in speed, accuracy, and machine utilization. The high-speed 3-axis linear drive system combined with AMADA�s original Variable Beam Control Technology allows the REGIUS to provide unmatched productivity while processing different materials. The REGIUS is also packed with features to support autonomous operation such as lens monitoring, collision recovery, and automatic nozzle change & centering.

2022 top rated affordable laser tube cutting machine with fiber laser source is an automatic CNC metal pipe cutting system used to cut patterns in square, round, rectangular, oval, and special shape tubes. Now the best budget fiber laser tube cutter for sale at cost price.