Laser Engraver

Fiber lasers are centered around the laser source. There is no gaseous medium inside them like CO2 lasers.

MCWlaser Pro laser engraver comes in three versions: 20W-30W, 50W, and 50W. These lasers emit a wavelength of 1064nm.

What are the disadvantages of laser cutting

Trying to figure out which Fiber Laser cutting machine is right for you? Contact our team to learn more about how our tools can craft anything you have in mind.

Some acrylic that is made of PVC emits toxic fumes when it is heated. You should always verify the chemical composition of the materials that you are going to engrave.

The laser beam generated is amplified, then fed to the cutting head via a flexible optical fibre.

FSL Muse Pandora comes pre-assembled. All you have to do is connect it with the necessary accessories and power it up.

Fiber lasers are centered around the laser source. There is no gaseous medium inside them like CO2 lasers.

MCWlaser Pro laser engraver comes in three versions: 20W-30W, 50W, and 50W. These lasers emit a wavelength of 1064nm.

A fiber laser shines in engraving applications. It can mark, etch and engrave metals at incredible speeds.

Fiber laser's narrow focal diameter makes it a great choice for high-contrast permanent engraving applications.

FSL Muse Pandora is 20W and can deep engrave gold at a rate of 708 ipm. It uses 100% of the laser's power.

Our machines can easily cut stainless steel, brass as well as aluminum and brass without the fear of back reflections. These fiber lasers machines will greatly reduce maintenance and operational costs.

LaserWorks or RDWorks software are used to control the machine. You can get them free from their websites.

FSLmuse Pandora requires 254mm lens, 330mm lens, and 420mm lens to work in open settings. Only then the laser can effectively focus on the material.

Looking for the best Fiber Laser cutting machine? Our team can help you create any item that you may have in mind.

Boss Laser offers the FM-Desktop laser engraver in 20W, 30W, and 50W fiber laser configurations. You can choose them depending on your work requirement.

Marking and engraving are improved by high peak power and nanosecond pulses. The increased power and improved beam quality result in cleaner cut edges and faster cutting speeds. Fiber lasers are also used in material processing, telecommunications, spectroscopy, medicine, and directed energy weapons.

Options for payment The average laser can cost between $50,000 and $250,000, making it a significant asset to a business.

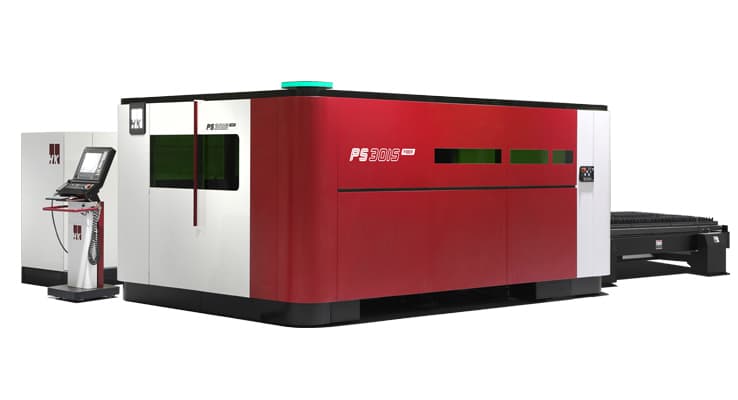

Laser fiber cutting machine

Fiber optic laser cutters are intended to cut metal at high speeds and with pinpoint accuracy. These machines, which have been on the market for more than 20 years, also use a fiber laser power source.