How much nitrogen does a fiber laser use

The enclosure features a motorized opening. It works in desktop configurations of FSL Muse Pandora.

MCWlaser PRO laser cutter has two versions, 20W, 30, and 50W. These lasers are 1064nm in wavelength

Fiber Lasers Machinery 010

�This investment enables us to fabricate parts like we have never been able to before. We can now offer companies prototyping through high-volume production.�

Boss Laser has CorelDRAW 2020 available as an optional add-on for the FM Desktop engraver machine.

MCWlaserPRO can be used to treat metals like steel, stainless and aluminum, silver, copper, alloy, aluminum, and others.

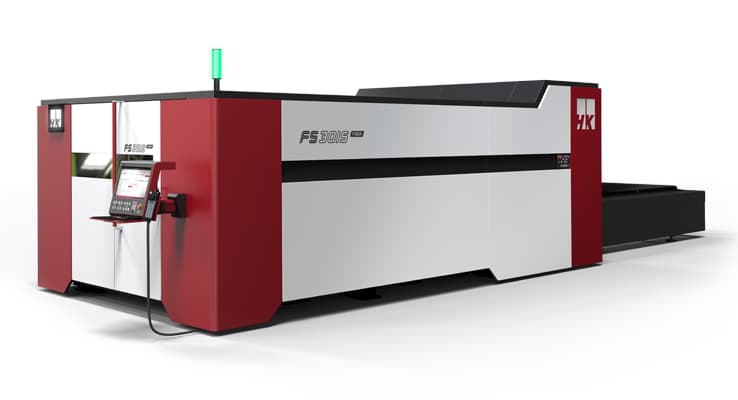

Are you trying to find the right Fiber Laser cutting machine for your needs? Get in touch with our team to find out more about our tools and how they can create anything you envision.

The enclosure features a motorized opening. It works in desktop configurations of FSL Muse Pandora.

MCWlaser PRO laser cutter has two versions, 20W, 30, and 50W. These lasers are 1064nm in wavelength

I evaluated these fiber laser laser engravers and selected them based on their size, material ability, laser power upgrades, laser safety, line motion, and software.

Discover the latest in laser technology, featuring the fastest speeds, highest-quality cutting, and our new IRIS� Camera Positioning system.

Since the working medium adopted by the laser generator is in the form of an optical fiber, its features are affected by the transition properties of the optical fiber. The pump light entering the fiber generally has multiple modes, while the signal photoelectric may have multiple modes. Different pump modes have different effects on different signal modes, making the analysis of laser generators and amplifiers more complicated. The doping distribution in the fiber also has a great impact on the laser generator. In order to make the medium have gain characteristics, working ions (that is, impurities) are doped into the fiber. In general, working ions are evenly distributed in the core. However, the distribution of pump light of different modes in the fiber is non-uniform. Therefore, in order to improve the pumping efficiency, the ion distribution and the pumping energy distribution should be as close as possible. When analyzing the laser generator, in addition to the general principle of the laser generator discussed above, it must also consider its own features, introduce different models and adopt special analysis methods to achieve good analysis results.

LaserWorks or RDWork software is used to control the machine. These software can be downloaded free of charge from the respective websites.

As far as the material is concerned, the addition of the material itself or the coating on the material will produce components that are harmful to the human body at high temperatures, so it should be noted.

The laser source is at the heart of any fiber laser. A fiber laser does not use any gaseous medium like a CO2 one.

MCWlaser PRO laser engraving machine has three versions: 20W, 30W and 50W. These lasers can reach wavelengths of 1064nm.

If you stare at the fiber laser cutting machine for a long time, it will cause very serious damage to the retina of the eye. All operators must wear laser goggles. Do not operate and observe with eyes exposed. In the cutting path of the laser equipment, it is necessary to avoid the position of any part of the body, so as not to accidentally cause unnecessary injury.

To guide light, fiber lasers use an optical fiber cable made of silica glass. Because the resulting laser beam is straighter and smaller than with other types of lasers, it is more precise. They also have a small footprint, are energy efficient, require little maintenance, and have low operating costs.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

Power consumption is extremely low.

A 3000W fiber laser requires 10kW of power plus 5kW for a chiller, for a total of 15kW. $2,700 per year at a rate of 15kW per hour for 12 hours.