Fiber Laser Machine Operator

I evaluated these fiber laser laser engravers and selected them based on their size, material ability, laser power upgrades, laser safety, line motion, and software.

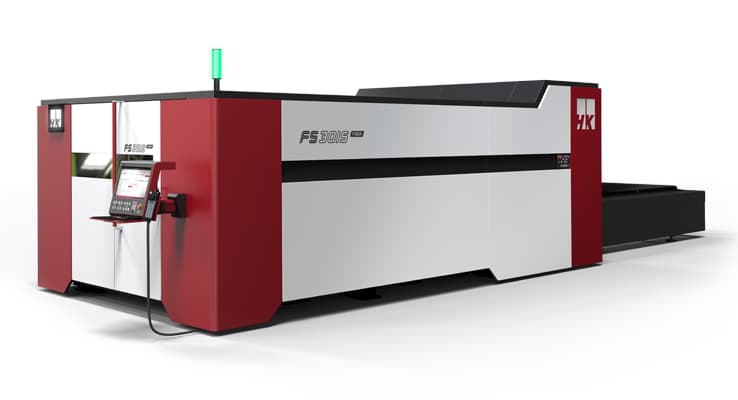

Discover the latest in laser technology, featuring the fastest speeds, highest-quality cutting, and our new IRIS� Camera Positioning system.