Infrared Spectrum

Its laser source module's footprint is 8.3"x14.9", and its engraving machine modules have a work area 13.8x22".

Finally, the laser beam is shaped at the cutting head using focus lenses and is projected on the work materials.

Indiamart

Fiber lasers are the best option for laser cutting/engraving aluminum and brass workpieces.

Gulf States Saw & Machine Co. provides an EZCAD2.0 software for controlling the Gulf States Saw & Machine Co. FM1212-50S lazer engraver.

FSL Muse Pandora is able to raster or vector engrave aluminum, steel and nickel as well as silver, titanium, copper, and stone.

FSL Muse Pandora comes pre-assembled. You just need to connect the accessories and turn it on.

Its laser source module's footprint is 8.3"x14.9", and its engraving machine modules have a work area 13.8x22".

Finally, the laser beam is shaped at the cutting head using focus lenses and is projected on the work materials.

MCWlaser PRO has an adjustable Z-axis, moved manually up and down with a control wheel. Unfortunately, XY axes are not adjustable.

A 30W or 50W fibre laser is required to improve the engraving area to 7.87 x 7.87 x 11.87 x 11.87".

A special type of fiber laser known as MOPA fiber laser, provides greater control over pulse width and frequency parameters to produce color laser engravings on metals.

It means that when working with metals that reflect laser beams they absorb fiber laser light much faster than the CO2 laser light.

RetinaEngrave can import file types such as PDF, SVG or JPG into RetinaEngrave.

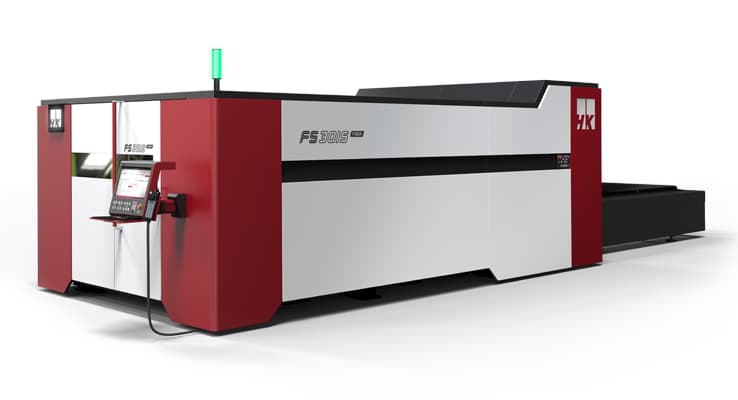

With the CNC control system, the fiber laser cutter is equipped with a laser generator to dope the pump material into the optical fiber, and the laser of a specific wavelength emitted by the semiconductor laser is coupled to make the optical fiber generate laser light. Then, the machine converges the laser beam into a small diameter spot to form a beam of high energy density and extremely bright light, which acts on the metal to be cut, which causes the temperature of the metal at the laser irradiation point to be sharp it rises and reaches the vaporization temperature instantaneously, causing evaporation and forming holes. And the machine uses this as the starting point, according to the shape requirements of the part to be cut, the laser beam and the part are moved relative to each other according to a certain trajectory to form a slit. At the same time, the auxiliary gas blowing device is used to remove the slag.

Triumph Laser comes with a computer as well as a foot switch, rotary and laser axes, 200mm lenses, laser goggles and a tool set for using the 30W desktop laser.

Buy safety glasses to protect this machine from the 1064 nm laser beam.

Fiber lasers typically cost between $20,000 and $45,000.

What Materials Can Be Cut With A Fiber Laser? A fiber laser cutting machine can cut sheet metal such as carbon steel, stainless steel, copper, brass, aluminum, and titanium. Fiber lasers outperform CO2 lasers in cutting reflective materials.

The wavelength is the primary distinction that determines the types of materials that each laser can process. The wavelength of a fiber laser is typically 1,060 nm, whereas CO2 lasers have wavelengths in the 10,600 nm range. Fiber lasers have many advantages over CO2 lasers in general.