Wavelength

Based on the 3D data, the auto-focus feature automatically adjusts laser head position along Z-axis.

FSL Muse Pandora uses a mirror galvanometer to trace the laser path and give an idea of what cuts it will make.

Fiber Lasers Machinery Price In Alabama

The High Speed SKYWAY delivers all of the cost saving advantages of the previous sorting system, but with unmatched performance.

Gulf States Saw & Machine Co. offers an EZCAD2.0 laser control program with the Gulf States Saw & Machine Co.'s FM1212-50S laser engraver.

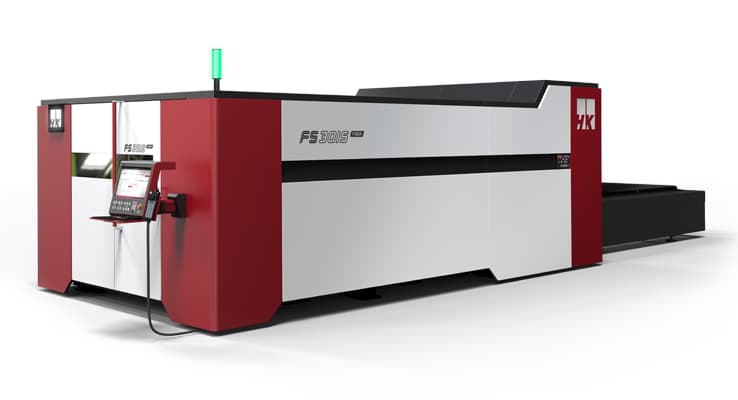

Dual-purpose fiber laser cutting machine is a commercial laser cutter system with dual functions to cut sheet metals, metal plates, metal tube, and metal pipes of steel, aluminum, alloy, titanium, copper, brass, iron, and other metal materials.

EZCAD 2.0, a free program that is compatible with Microsoft Windows XP/Windows 2000 and Windows 7, WIN8, WIN 10, OS.

Based on the 3D data, the auto-focus feature automatically adjusts laser head position along Z-axis.

FSL Muse Pandora uses a mirror galvanometer to trace the laser path and give an idea of what cuts it will make.

Other accessories, such as lenses or fume extractors, can be purchased to enhance the machine.

A fiber laser can be limited in both the size of the work-bed and the materials that you can cut.

MCWlaser PRO includes a Z-axis. It can be moved manually with a control knob. Unfortunately, the XY and Z axes can't be adjusted.

Fiber lasers are widely used in engraving applications, and their wavelength ranges between 780nm - 2200nm.

Auto-focus automatically adjusts laser head position on the Z-axis based on data received from the 3D cam.

For after-sales services, you can contact them through phone, e-mail, or through their social media handles.

It is free-to-use software that can be used on Microsoft Windows XP or Windows 2000, WIN 7, WIN8, WIN 10 OS.

A fiber laser shines when it comes to engraving. This laser can mark, etch, or engrave on metals with amazing speed.

To guide light, fiber lasers use an optical fiber cable made of silica glass. Because the resulting laser beam is straighter and smaller than with other types of lasers, it is more precise. They also have a small footprint, are energy efficient, require little maintenance, and have low operating costs.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

Power consumption is extremely low.

A 3000W fiber laser requires 10kW of power plus 5kW for a chiller, for a total of 15kW. $2,700 per year at a rate of 15kW per hour for 12 hours.