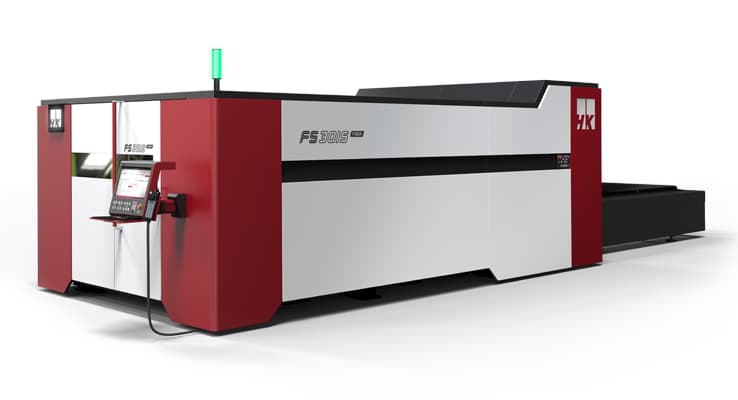

Fiber lasers are solid state lasers that are widely used in laser marking and engraving machines. Laser cutting sheet metal is the major difference between a fibre laser and a co2 laser.

Fiber laser machines are more efficient in cutting thin metals. A fiber laser can efficiently cut thin metals to 25mm, or 1 inch. After this point, fiber lasers become less efficient at cutting metal. You'd need to use a lot of power, which would also cost more, in order to cut ticker metallics over 25mm or one inch.