Can a laser cut a human

Amazon offers a 30-day return policy.

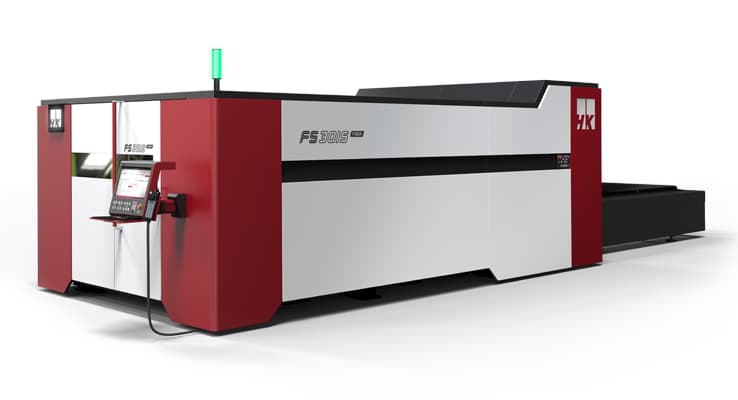

Laser machines can be used to cut almost any type of material. The kind of laser machine used will affect the materials you can cut. However, a CO2 laser can cut through metals like copper, aluminum, and brass. They can however cut through nonmetallic substances like wood or plastic.