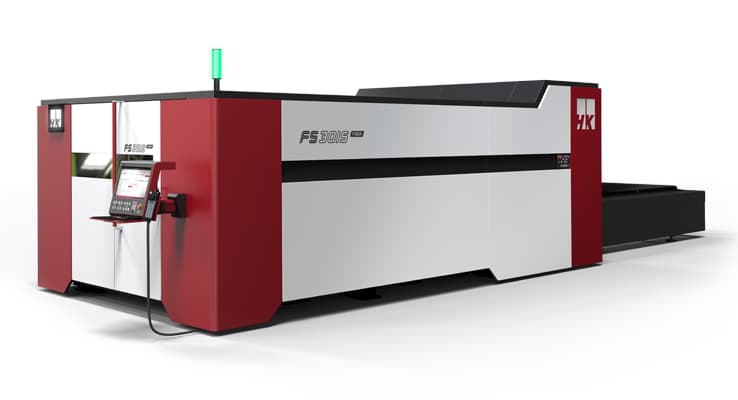

Fiber Laser Cutting Machine Installation

Fiber lasers can be used to engrave metals more efficiently than the generic CO2 lasers.

If the fiber lasers have enough power, they can cut through reflective substances. They can cut any kind of metal, provided they have enough power. They will be limited in the thickness that they can cut.