Box And Pan Brake Vs Press Brake

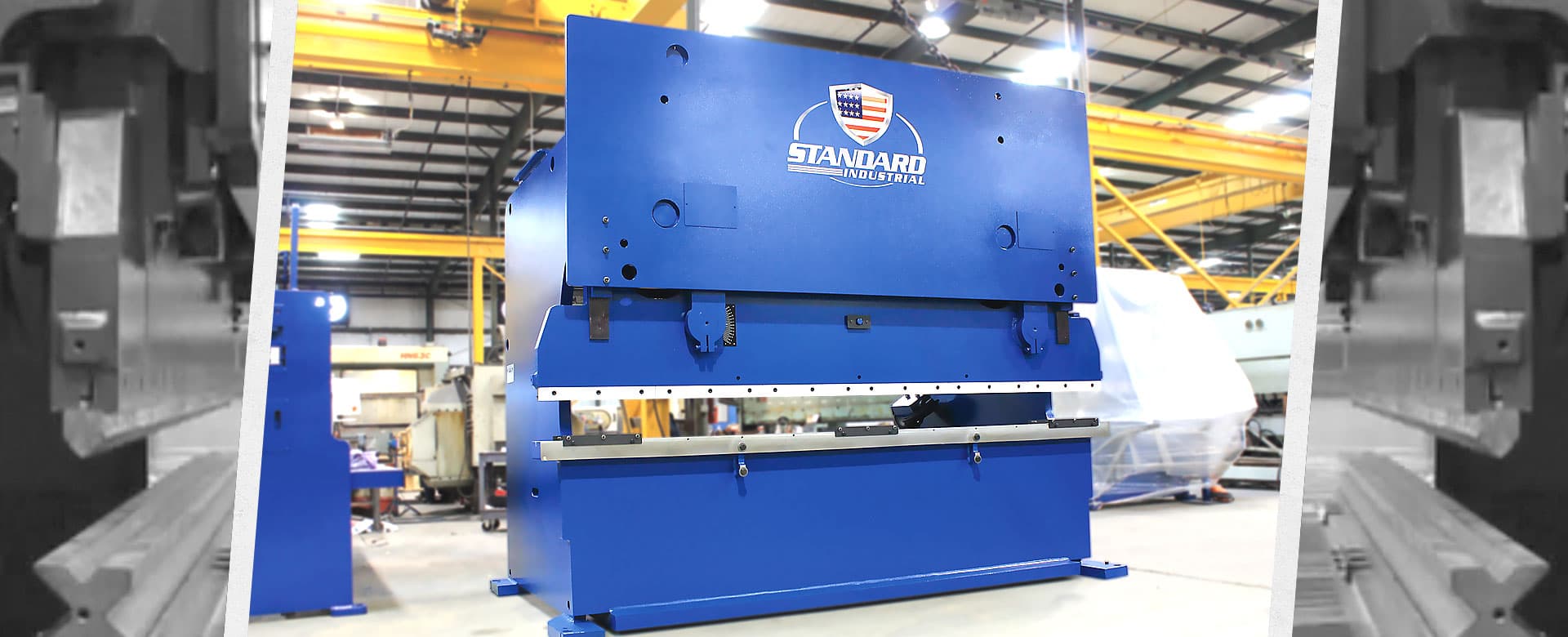

Single Cylinder Press Brake 203

Hydraulic press brakes can be used for heavy-duty work. They can also be customized to meet customer requirements, from high tonnage to long-length tandems and everything in-between.

Our machines are built with industry-leading production capabilities and feature intuitive operator controls that reduce stress for all skill levels.