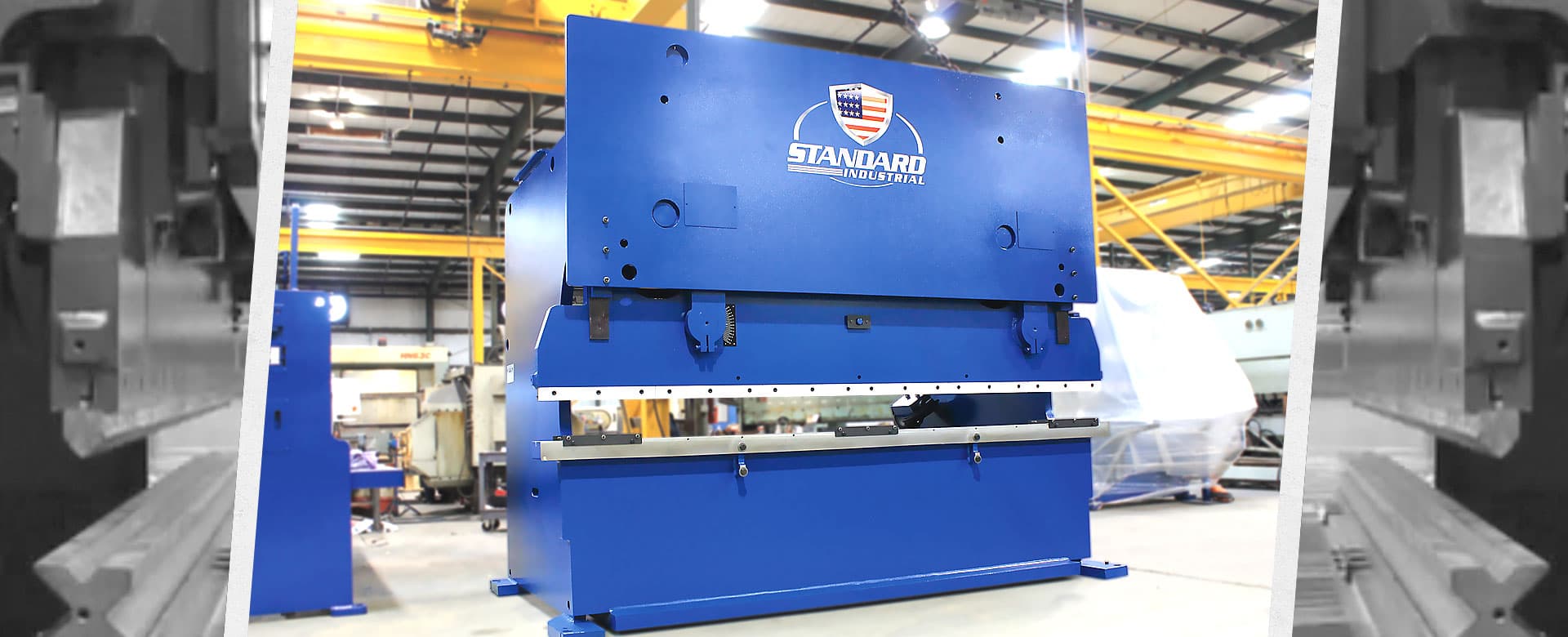

Single Cylinder Press Brake Ebay

Tooling Style

With a hydraulic presse brake, it is important to produce the highest quality parts as quickly as possible. The Piranha Easy Crown system has made this even easier. It bypasses the most common problem when using a hydraulic brake: deflection.

Real-time information from this game-changing tool changer lets any press brake operator perform better.